Boat Chat’s mission is ‘Helping people understand boats better’. It contains a mixture of maritime news, boat maintenance advice, marine surveying tips, product reviews and other boat related stuff.

To help Boat Chat keep delivering maritime value to your inbox for free please show us your appreciation and support by

To help Boat Chat grow, please forward this email to your friends, colleagues and contacts who have an interest in boats.

In this edition of Boat Chat:

Maritime News - Narrowboats explode or get left high and dry

Boat Chat Focus - “How Thick Do You Have To Be?”

Latest YouTube Video - Surveyor said “Walk Away” But I Bought It Anyway

Surveyor’s Top Tip - Be Thick, Fit Anodes And Paint It

Great Kit Ideas

TLDR:

Owning a boat brings with it many challenges, some of which you can control and some of which you can’t. Be flexible, be prepared and keep a good sense of humour!

Maritime News

Electric Narrowboat Explodes On Oxford Canal

On the morning of August 5 an electric narrowboat caught fire and exploded at Gayton Marina in Northamptonshire.

E-Narrowboat Explodes At Gayton Marina

The vessel was typically used for day charter use, operated by ABC Leisure. Thankfully it was on charge and unoccupied at the time of the explosion.

The boat was reportedly fitted with Lithium Iron Phosphate batteries (LiFePO4) batteries, which are typically used to power electric vehicles. LiFePO4 batteries are widely considered the composition of choice for this application and have a generally good reputation for being stable and less likely to enter thermal runaway.

The cause of the accident has not been determined and the craft was destroyed.

Canals Run Dry Leaving Boats Stranded

Several canals in the UK have experienced very low water levels this summer. This has closed some canals to navigation, impacted canal-side businesses and marinas and left many boats stranded by the canal sides.

Boat beached By Low Water In Canal

Matthew Symonds from the Canal & Rivers Trust commented: “Our canal network is feeling the strain after one of the driest springs on record and several heatwaves this summer”. With little or low levels of rain currently in the forecast, the situation isn’t set to improve in the near term.

Boat Chat Focus - “How Thick Do You Have To Be?”

Boat Chat is part way through re-writing the Surveying Inland Waterways Craft module of the IIMS’ Marine Surveying Professional Qualification. During a recent conversation with inland waterways marine surveyor Darrell Broscomb about the content, we lamented that there is still no industry accepted definition of the minimum insurable thickness for a steel hull. Indeed, if you ask a group of marine surveyors, boat builders and insurers and you’ll be sure to get a broad range of answers with no real consensus.

Is 2.2mm Thick Enough?

So how best to approach the ‘How thick do you have to be?’ question? The first is to look at how thick the steel plate should be when the boat is built. Several methods for doing this, and in their excellent discussion paper ‘Minimum Steel Thickness For Narrowboats’ (2022) Tom Keeling and Peter Brookes draws on several methodologies to suggest an acceptable minimum thickness for the industry.

Depending on which method one uses, the minimum plate thickness should be 3mm to 5.0mm plate as an appropriate scantling for building a typical 50’ narrowboat. Yet with the industry average for new builds being 10-6-4 (10mm bottom, 6mm sides, 4mm top), most narrowboats are very over-engineered.

The actual thickness of steel plate manufacture is quoted as ‘nominal’ which is not the same as ‘actual’. This is defined in BS EN 10029:2010 and depending on the grade of steel used this variation could mean 6mm plate that is anywhere from 5.25mm to 7.20mm thick. So building in a little thickness safety margin at the specification stage is useful.

Given the above, how should we look at thickness loss with a view to insurability and repair decisions? There are two pathways to consider what to do when steel has become thin. The first is by having an absolute figure for minimum thickness such as 3.0, 3.5 or 4.0mm defined in surveying practice and accepted by insurance companies. This is a nice simple option until we find the plate used at build was only 4mm or less! Does that mean all lightly built inland waterways craft are therefore uninsurable?

Or we can assess thickness loss be by setting a maximum percentage loss than can be lost from the original plate thickness. For example, if we will not accept more than 25% thickness loss then a 6mm plate would be condemned when the pitting or loss exceeds 1.5mm (leaving 4.5mm of steel in the pit ) as would a 10mm plate with 2.5mm pits (7.5mm pit depth thickness). This would render a huge number of hulls uninsurable whilst still having more than 4mm of steel thickness remaining.

There are no easy answers to the ‘How thick do you have to be?’ question and in many ways the conclusion is:

“It depends’.

It depends on not just the thickness of the steel specified at build but also the quality of the steel. There is a wide range of steel plate and the price for quality steel plate approved by Lloyds for example is significantly higher than for ‘run of the mill’ plate. It also depends on how well the steel was prepared and painted at build and how well that has been maintained. Finally it depends on the types of corrosion active on the hull and the time they are allowed to develop.

The decision to condemn a hull must never be taken lightly and every surveyor needs to exercise caution when doing so. The methodology used will inevitably vary from survey to survey due to the variety of factors present that influence the decision and the surveyor must define what their reasoning was in reaching the decision. Just because a hull has thinned to a certain degree, does not automatically mean it is not fit for service. There is always a context to consider.

For example, on a 10-6-4 narrowboat with extensive pitting at 30% or more of original thickness, re-plating or overplating sections may be the best decision, whilst isolated deep pits at over 30% could be pad welded. General thickness loss to below 4mm may necessitate re-plating or overplating. Or perhaps the decision might be to blast the steel back to SA2.5 and re-paint with quality 2-pack epoxy paints. But on a hull that was made from 4mm steel, the methodologies used need to be put into a more specific context, considering the quality of the steel and age and use of the vessel and the surveyor’s decision reached should reflect this. Given all of this, it is no wonder that there isn’t a magical number to which we can all agree, as every hull is a unique creation which demands an individual approach.

It’s an ongoing debate so please drop your thoughts into the comments.

N.B. As always, it must be said that re-plating is always the preferred repair option and overplating, whilst far more common (and convenient), should only ever be viewed as an expedient repair. That however, is the subject for another issue of Boat Chat.

Boat Chat Growth

Boat Chat continues to grow well and now has over 800 subscribers across all platforms.

Alongside that, the White Hat Marine Surveying YouTube channel continues to upload videos for boat owners, buyers, brokers and surveyors and is nearing 2,000 subscribers. The mission remains:

‘Helping People Understand Boats Better’.

In the most recent YouTube video David Pestridge provides an update on a 53 year old steel Dutch motor cruiser which he surveyed in July and advised his Client to “Walk Away”.

Surveyor’s Top Tip for this month - There are three key things you need to do to preserve your steel hulled boat. Start with the thickest steel you can, fit anodes at the right scaling and composition and use the best quality paints you can afford inside and out and keep it painted (INCLUDING THE BOTTOM PLATE). Not doing all three means corrosion is inevitable.

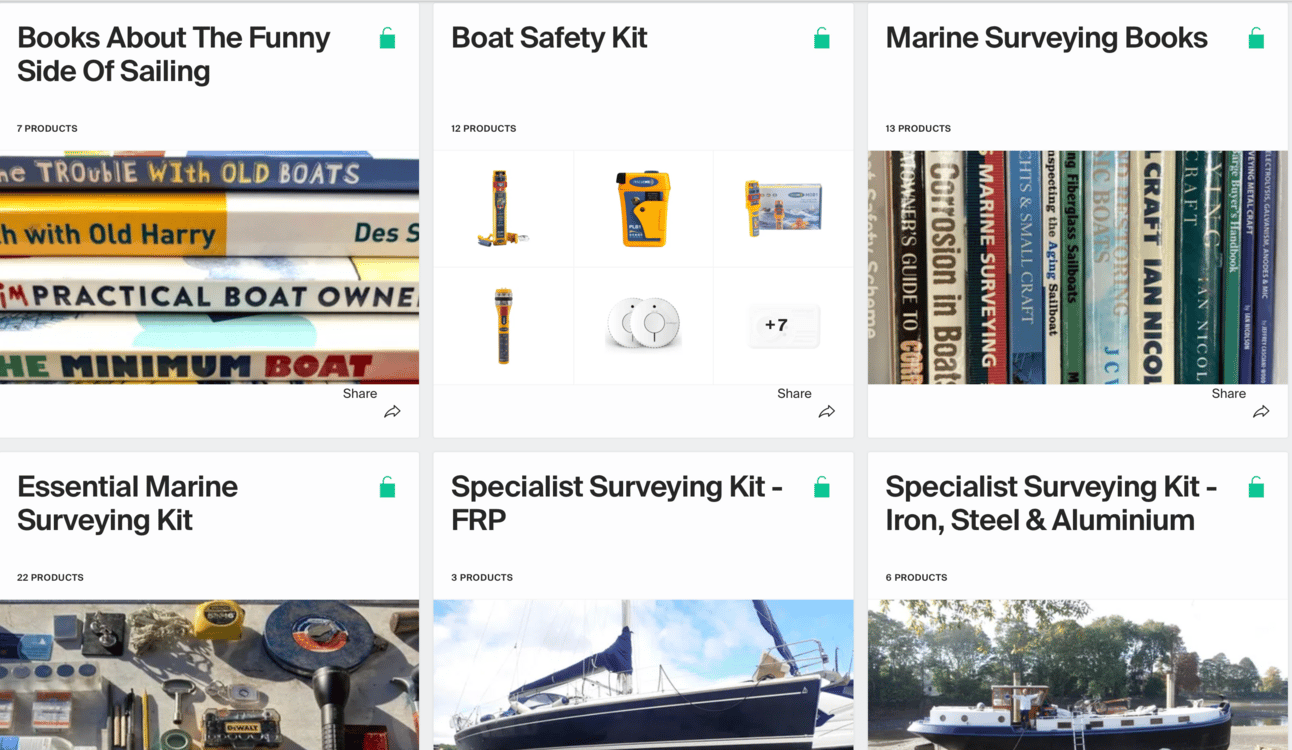

Great Kit Ideas

With the boating season in full swing, why not treat yourself to some new gear for the boat owners or marine surveyors in your life or as a treat for your boat. I have put together several collections on Kit.Co which are all personally recommended items and most of which I own.

From boat safety equipment to books about sailing and the tools and books a marine surveyor needs; there really is something for everyone!

Boaty Terminology

Stranded - A boat left aground on a shore

How You Can Support Boat Chat

To help Boat Chat keep delivering maritime value to your inbox for free please show us your appreciation and support by Buying us a beer

We did mention that Boat Chat was FREE didn’t we?

And Finally…. 👍🏻

Please don’t forget to share this newsletter with your friends, colleagues and contacts who have an interest in boats. If you have any great ideas for future content you think would be good or want to discuss collaboration opportunities, please throw Boat Chat a line at:

And Finally, Finally…

Please note that any links to products in this newsletter are typically Amazon Affiliate Links which may earn Boat Chat a small commission should you buy them using the link (this does not affect the price you pay).